Project Services

We deliver industry-leading turnkey protective coating and lining projects, offered in a shop facility, on-site, or both. Apache has an approach to projects that has been evaluated and has weathered complex deliverables. Whether the project is large or small, capital, turnaround, maintenance, or specialty, Apache provides safe and qualified craft, supervision, expertise, quality, and controls to produce specification-compliant projects. At the heart of what we do is the application of coatings and linings to defend against corrosion, protecting people and assets.

Capital and Turnaround Projects

-

Capital and Turnaround Projects

-

Shop Facilities

-

Above-Ground Storage Tanks

Capital and Turnaround Projects

Apache has a long history of performance on capital and turnaround projects. We are able to supply qualified supervision and labor—including inspection, proven project controls to accurately track progress and alignment with schedule, and documentation to support the project.

Shop Facilities

Apache has multiple facilities; five (5) of those shop facilities are located along the Texas/Louisiana Gulf Coast, and all have access to major highways. The largest shop, located in the Houston area, sits on 125 acres with 300,000 square feet under roof, capable of processing over 3,000 loads annually. Apache shops support projects such as modules, vessels, structural steel, frames, fabricated, straight-run pipe, tank plate, and specialty projects, and can perform turnkey projects combining shop coatings, fireproofing, thermal spray, and insulation.

Above-Ground Storage Tanks

At Apache, we excel at tank projects. Cone roof tanks, external floating roof tanks, spheres, clarifiers, new tanks, existing tanks, welded tanks, riveted tanks, concrete tanks … TANKS. We have more than 30 years using experienced craft and crews and company-owned equipment, including plural component pumps and automated blasting equipment, with the ability to employ the right combination of people and equipment on a project-by-project basis.

Project Expertise

Apache offers the following industrial coating services for a wide variety of applications and industries.

- Lead abatement

- Reinforced linings

- Thermal spray—arc and flame

- Concrete/secondary containment

- CUI projects/programs

- Insulative coatings

- Spray foam insulation

- Tape wrap systems including composites

- Pipeline epoxies and AROs

- Soil to air interface

- Force cure linings

- Automated blasting

- Large fleet of company-owned equipment

- Vapor blasting

- Plural component spray

- Enclosures

Protective Coating and Lining Applications and Industries Served

Apache has established itself as the industry leader in protective coating and lining services, having a proven history of project support through qualified supervision and workforce, shop facilities, and company-owned equipment to back it up.

- Midstream/pipeline

- Refining, chemical, and petrochemical

- Power generation

- Data centers / technology manufacturing centers

- Experienced leadership trained and certified by AMPP, formerly National Association of Corrosion Engineers (NACE) and Steel Structures Painting Council (SSPC)

- More than 20 Level III NACE Coatings Inspectors on staff, more than 40 Level I and II

- Trained and experienced coatings applicators

- Multicraft projects—integration and coordination

- Superior tank linings and tank maintenance services

- Lead abatement in accordance with OSHA and EPA standards

- Dedicated offshore production platforms and coatings teams

- Thermal Spray Coatings (TSC/TSA) solutions

The Apache Difference

The pride that our team members experience every day reflects the importance we place on our people, whose actions serve as the backbone of our operations. They define who we are, drive performance, and ensure the highest degree of safety. No other company in this industry recruits, trains, and develops their employees to become expert craft professionals like Apache Industrial.

Other Services

Refractory

Apache provides a single point of contact for refractory projects in system design support, cause of failure investigation, preplanning, project execution, and QA/QC. Our fleet of equipment is the newest and highest-rated in the industry.

Fireproofing

Apache performs fireproofing at the highest level of service in the industry. We are a certified applicator of virtually all intumescent epoxy passive fire protection coating systems, as well as several lightweight cementitious systems.

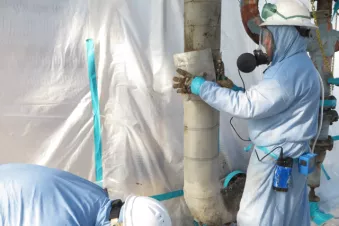

Insulation

Apache handles insulation projects ranging from asbestos concerns to corrosion-prevention measures, emphasizing customer-specific solutions and cost savings. Our skilled and knowledgeable craft professionals execute maintenance, capital, and turnaround projects safely and efficiently.

Abatement

Apache’s abatement experts are certified and trained to complete any size abatement project, including lead, asbestos, and mold containment, using state-of-the-art methodology including mechanical, chemical, vacuum, wet, and abrasive blasting.

Get Started

Talk to one of our experienced professionals about your next project and discover what Apache Industrial can do for you.