Refractory Services

Our robust Refractory Division serves as a single point of contact for any industrial refractory services project by providing a full array of services, including system design, installation, maintenance, repair, support, failure inspection, preplanning, project execution, and quality assurance/quality control (QA/QC).

Membranes and Welding

-

Membranes and Welding

-

Cast Linings

-

Ceramic Fiber Linings

-

Dry Gun Linings

-

Wet Gun Linings

-

Rammed Linings

-

Brick Linings

-

Injectables or Pumpables

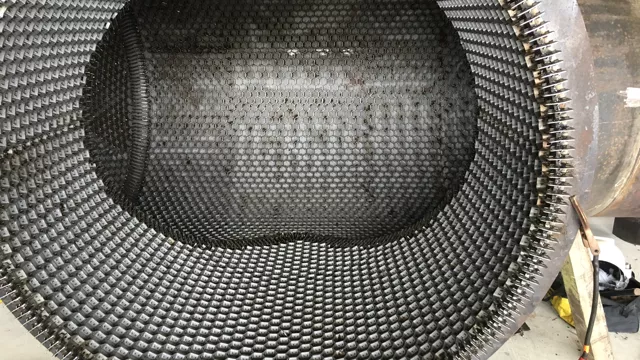

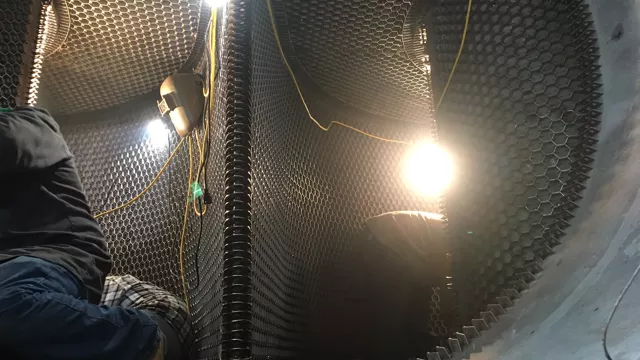

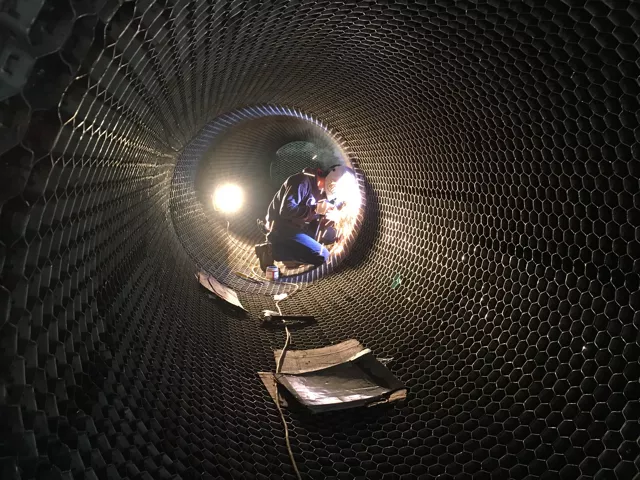

Membranes and Welding

Refractory membranes are typically made from materials and metal alloys that have a high melting point and excellent chemical resistance. These materials can withstand temperatures of up to several hundred degrees Celsius without degrading and can also resist corrosion and erosion from harsh chemicals. At Apache, we understand that petrochemical, industrial, and energy businesses work in very challenging environments. To ensure that your projects run on time and meet your budget, you need refractory metal welding that can provide high-temperature strength and corrosion resistance.

Cast Linings

Refractory castable linings are commonly used in industrial settings like kilns, furnaces, FFCU units, and boilers, where they protect the underlying structure from the extreme heat of the process. They can be custom formulated to meet specific temperature and chemical resistance requirements, making them a versatile option for a wide range of applications. Refractory castable lining is ideal for industrial furnaces, pipes, and equipment that operate at high temperatures. The linings protect the structure from erosion, abrasion, thermal shock, and wear, significantly reducing the chances of any equipment stoppages and accidents.

Ceramic Fiber Linings

Ceramic fiber refractory linings are typically used in applications where thermal insulation is required, such as furnaces, kilns, and incinerators. They are also used where space is limited, as they can be installed in thin layers and still provide effective insulation. Apache uses the latest technology and the best ceramic fiber lining available on the market.

Dry Gun Linings

Dry gunite lining is used in high-temperature applications such as furnaces, boilers, FFCU units, and kilns. These materials have excellent resistance to thermal shock and chemical attack, making them ideal for use in harsh industrial environments. It’s quick and easy to install, requires little maintenance, and reduces emissions.

Wet Gun Linings

Wet gunite refractory lining is used in high-temperature applications. Unlike dry gunite refractory lining, which uses a dry mix of refractory material, wet gunite refractory lining involves spraying a wet mix of refractory material onto the surface to be lined.

Rammed Linings

Rammed silica lining is a type of refractory lining that is made by ramming or packing silica-based refractory materials into place using a pneumatic or hydraulic ramming gun. Silica is a naturally occurring mineral that is commonly used in refractory applications due to its excellent thermal properties and high resistance to thermal shock.

Brick Linings

Brick refractory lining involves laying individual refractory bricks in a specific pattern to create a durable lining that is resistant to high temperatures and chemical corrosion. Refractory bricks are made from a variety of materials, including high-alumina, fire clay, and silica. These materials are chosen for their ability to withstand high temperatures and their resistance to thermal shock and chemical attack. Brick refractory lining is durable and relatively easy to repair, as individual bricks can be replaced as needed. It can be used in a wide variety of applications, including furnaces, boilers, SRU units, and kilns.

Injectables or Pumpables

Injectable or pumpable refractory lining is installed by pumping or injecting a flowable mixture of refractory material and a bonding agent into the area to be lined. This type of lining is often used in areas where traditional brick or castable refractory linings are difficult or impractical to install, such as complex shapes, hard-to-reach areas, or areas with limited access. Once the injectable or pumpable refractory lining material is in place, it cures and hardens to form a dense and durable lining that is resistant to high temperatures and chemical corrosion. This type of refractory lining is typically used in high-temperature applications such as furnaces, kilns, and boilers.

Benefits

Our expert leadership team and front-line managers have worked together for more than 25 years. Backed by such extensive experience, our industrial refractory division can help you realize many benefits and advantages:

- Safeguard and protect capital investments including costly manufacturing and processing equipment

- Enhance durability by providing resistance to high heat, corrosion, and chemicals

- Extend service life and enhance equipment productivity and efficiency

- Reduce maintenance costs, equipment failure, and plant and equipment downtime

- Enhance energy savings

- Improve workforce and plant safety

- Prevent leaks and spills

- Increase thermal protection

- Increase asset lifecycle and value

Refractory Applications and Divisions

As a leading industrial refractory materials and services contractor, Apache offers the following array of services for a wide variety of applications and industries.

- Membranes and welding

- Refractory anchorage

- Cast linings

- Ceramic fiber linings

- Dry gun linings

- Wet gun linings

- Rammed linings

- Brick linings

- Injectables and pumpables

Apache has established itself as the industry leader in industrial refractory services with the proven track record, facilities, tools, and personnel to back it up.

- All supervision is API 936 certified

- ICA5301 Shotcrete certification

- Proven history and track record of successful turnaround projects on fluid catalytic cracker units (FCCUs) and fired heaters and furnaces

- Stick welding or inverted drawn arch technology

- Project QC records provided in multiple formats indicating all repair locations

Experienced Leadership Team and Front-Line Manager

We have extensive experience working with a wide variety of furnaces, boilers, and other thermal-processing equipment of all sizes and complexities. We understand that refractory services are a vital component to the preservation and performance optimization of expensive industrial manufacturing and processing equipment that utilizes high heat. We use the most advanced technology, innovative methods, and high-quality refractory materials that result in better equipment performance, increased safety, significant cost savings, and decreased downtime and maintenance. Additionally, our fleet of equipment is the newest and highest rated in the industry, which includes our industry-leading Allentown gunite rigs.

The Apache Difference

The pride that our team members experience every day reflects the importance we place on our people, whose actions serve as the backbone of our operations. They define who we are, drive performance, and ensure the highest degree of safety. No other company in this industry recruits, trains, and develops their employees to become expert craft professionals like Apache Industrial.

Other Services

Fireproofing

Apache performs fireproofing at the highest level of service in the industry. We are a certified applicator of virtually all intumescent epoxy passive fire protection coating systems, as well as several lightweight cementitious systems.

Coatings and Linings

Apache has extensive coatings and lining expertise in both shop and field projects, including fabricated pipe spools, straight-run pipe, tank plates, structural steel, modules, pressure vessels, and more—all supported by our experienced and credentialed quality inspection team.

Insulation

Apache handles insulation projects ranging from asbestos concerns to corrosion-prevention measures, emphasizing customer-specific solutions and cost savings. Our skilled and knowledgeable craft professionals execute maintenance, capital, and turnaround projects safely and efficiently.

Scaffolding

Apache will design, install, and dismantle scaffolding for any type of application, utilizing both pin-lock and cup-lock type scaffolding systems. Our scaffold storage yards are strategically located to service the scaffolding needs of customers across North America.

Get Started

Talk to one of our experienced professionals about your next project and discover what Apache Industrial can do for you.